Special Purpose Machines: References

Selected reference projects from the automotive, medtec and general industry sectors.

Sensors

Assembly and testing machine for AQI sensors

Assembly and testing machine

Function

Automatic assembly of AQI enclosures with assembly control and functional testing

Sub-function

Check for completeness of the assembly parts; checking the seal by means of BVS; assembly of the individual part; testing function: follow-up check; gross leak test; function check (PC-based testing technology)

Construction

Steel welding version of rotary indexing table machine as a standing workstation; with image processing system; safety and door circuit controlled; access security; safety grille

Loading plate dimensions:

60mm x 80mm x 110mm

Weight:

150 g

Function

Automatic assembly of AQI enclosures with assembly control and functional testing

Sub-function

Check for completeness of the assembly parts; checking the seal by means of BVS; assembly of the individual part; testing function: follow-up check; gross leak test; function check (PC-based testing technology)

Construction

Steel welding version of rotary indexing table machine as a standing workstation; with image processing system; safety and door circuit controlled; access security; safety grille

Loading plate dimensions:

60mm x 80mm x 110mm

Weight:

150 g

Chassis and engine mounts

Robot applications

Loading system for vulcanization press

Function

Fully automatic feeding and loading of the vulcanization press

Sub-function

Loading plate for holding 3 inserts in 8x8 (64-fold) grid; feeding of inserts by feeding units; orientation, separation and application of inserts in loading plate

Construction

Robot product: Kuka KR 500; platform construction; communication with feeding units and vulcanization press; guard with protective barrier system; access areas with safety light grid

Loading plate dimensions:

1500 mm x 1250 mm x 200mm

Gewicht:

270 kg

Function

Fully automatic feeding and loading of the vulcanization press

Sub-function

Loading plate for holding 3 inserts in 8x8 (64-fold) grid; feeding of inserts by feeding units; orientation, separation and application of inserts in loading plate

Construction

Robot product: Kuka KR 500; platform construction; communication with feeding units and vulcanization press; guard with protective barrier system; access areas with safety light grid

Loading plate dimensions:

1500 mm x 1250 mm x 200mm

Gewicht:

270 kg

Oral care

Palleting systems

Palletizer for brush discs

Function

Palletizing brush discs

Sub-function

Separation of the fed brush discs on the setting distance in the tray, feeding the empty trays in the stack, filling the top tray, setting down the filled tray in the stack on the discharge line

Construction

Single cell, steel welding frame, enclosure with transparent panels

Loading plate dimensions:

1500 mm x 1250 mm x 200mm

Weight:

270 kg

Function

Palletizing brush discs

Sub-function

Separation of the fed brush discs on the setting distance in the tray, feeding the empty trays in the stack, filling the top tray, setting down the filled tray in the stack on the discharge line

Construction

Single cell, steel welding frame, enclosure with transparent panels

Loading plate dimensions:

1500 mm x 1250 mm x 200mm

Weight:

270 kg

Mechatronic systems

Assembly system for roof modules

Assembly system for roof modules

Function

Semi-automatic assembly of roof modules for automotive sector; production according to data supplied; based on this data, the parts are inserted and checked for correctness (sequence production)

Sub-function

Manual insertion; double-workpiece carrier circulation system; insertion and testing station; assembly stations (manual and automatic); scanning and testing stations; manual removal

Construction

Welded steel design; double-workpiece carrier circulation system; linked single cells (16 stations); Siemens PLC; WinCC server with Web Navigator (6 HMI)

Roof light dimensions:

approx. 300mm x 220mm x 55mm

Function

Semi-automatic assembly of roof modules for automotive sector; production according to data supplied; based on this data, the parts are inserted and checked for correctness (sequence production)

Sub-function

Manual insertion; double-workpiece carrier circulation system; insertion and testing station; assembly stations (manual and automatic); scanning and testing stations; manual removal

Construction

Welded steel design; double-workpiece carrier circulation system; linked single cells (16 stations); Siemens PLC; WinCC server with Web Navigator (6 HMI)

Roof light dimensions:

approx. 300mm x 220mm x 55mm

Serial Machines

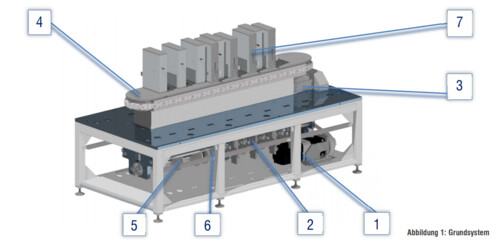

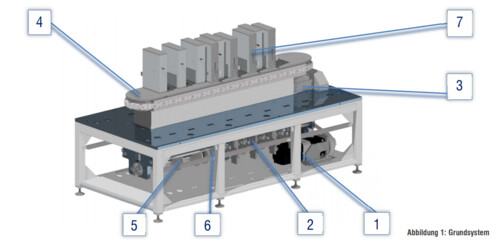

CDL - Cam Driven Line

Cam Drive Line

Concept

Combined, mechanically coupled cam-controlled transfer and handling system.

Basis for your assembly task. Up to 80 cycles per minute.

Structure & unktion

The central main drive (1) of the basic machine drives the horizontal main shaft (2) via a toothed belt and the indexing gearbox (3), wich directly drives the indexing chain of the transfer system (4). The monioned indexing gearbox has a shift angle of preferably 120 degrees. The required output movement of the gearbox is achieved by means of four stops for the tact chain. The main shaft is located below the table plate and carries the cam disc (5) that define the movements of the work stations. The describes movements reach the respective stations (7) via cam rollers and deflection levers (6) and connecting roods. The deflection levers are loaded with tension springs or optionally with pneumatic elements.

Dimension of the workpieces:

80mm x 80mm x 150mm, up to ca. 1000 gramms

CDL-Documentation_EN CDL-Documentation_FR

CDL-Price list CDL-Liste de prix

Compact Presentation CDL Présentation compacte CDL

Concept

Combined, mechanically coupled cam-controlled transfer and handling system.

Basis for your assembly task. Up to 80 cycles per minute.

Structure & unktion

The central main drive (1) of the basic machine drives the horizontal main shaft (2) via a toothed belt and the indexing gearbox (3), wich directly drives the indexing chain of the transfer system (4). The monioned indexing gearbox has a shift angle of preferably 120 degrees. The required output movement of the gearbox is achieved by means of four stops for the tact chain. The main shaft is located below the table plate and carries the cam disc (5) that define the movements of the work stations. The describes movements reach the respective stations (7) via cam rollers and deflection levers (6) and connecting roods. The deflection levers are loaded with tension springs or optionally with pneumatic elements.

Dimension of the workpieces:

80mm x 80mm x 150mm, up to ca. 1000 gramms

CDL-Documentation_EN CDL-Documentation_FR

CDL-Price list CDL-Liste de prix

Compact Presentation CDL Présentation compacte CDL

Miscellaneous

System integrator for testing systems

Testing and sorting machine for MIM parts

Function

Checking three types of exhaust gas turbocharger blades for dimensional accuracy

Sub-function

Manual loading of the workpieces into feeding unit; automatic parts throughput; provision of the parts by feeding unit and indexed forward through turnover handling in the stations: diameter test, wing inspection up to parts depositing; deposition by hand in bags (good parts) or NOK boxes

Construction

Welded steel frame; workpiece feed via oscillating conveyor system; test stations; parts depositing; safety housing

MIM part dimensions:

approx. 20mm x 28mm x 6mm

Function

Checking three types of exhaust gas turbocharger blades for dimensional accuracy

Sub-function

Manual loading of the workpieces into feeding unit; automatic parts throughput; provision of the parts by feeding unit and indexed forward through turnover handling in the stations: diameter test, wing inspection up to parts depositing; deposition by hand in bags (good parts) or NOK boxes

Construction

Welded steel frame; workpiece feed via oscillating conveyor system; test stations; parts depositing; safety housing

MIM part dimensions:

approx. 20mm x 28mm x 6mm

System integrator for laser machining systems

Laser welding machine for flexplates

Function

Automatic welding of flexplates (starter ring discs) with joined parts inspection

Sub-function

Manual loading and unloading position; parts transportation; joining part check (location + completeness); determination of welding gap width with correction value calculation (rotational speed + material allowance); welding cell; NC-controlled 2-axis portal to activate Galvo head; lifting rotary actuator for moving welding assembly under Galvo head; weld seam inspection with 2D laser cutting technology

Construction

Workpiece carrier circulation system: Bosch TS2; NC axis coupling via master-slave control ("cam controller")

Flexplate dimensions:

Ø: approx. 400 mm

Gewicht:

approx. 3 kg

Function

Automatic welding of flexplates (starter ring discs) with joined parts inspection

Sub-function

Manual loading and unloading position; parts transportation; joining part check (location + completeness); determination of welding gap width with correction value calculation (rotational speed + material allowance); welding cell; NC-controlled 2-axis portal to activate Galvo head; lifting rotary actuator for moving welding assembly under Galvo head; weld seam inspection with 2D laser cutting technology

Construction

Workpiece carrier circulation system: Bosch TS2; NC axis coupling via master-slave control ("cam controller")

Flexplate dimensions:

Ø: approx. 400 mm

Gewicht:

approx. 3 kg

Our customers

We can look back on many years of experience in the automotive, solar, medical technology and general industry sectors.